Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

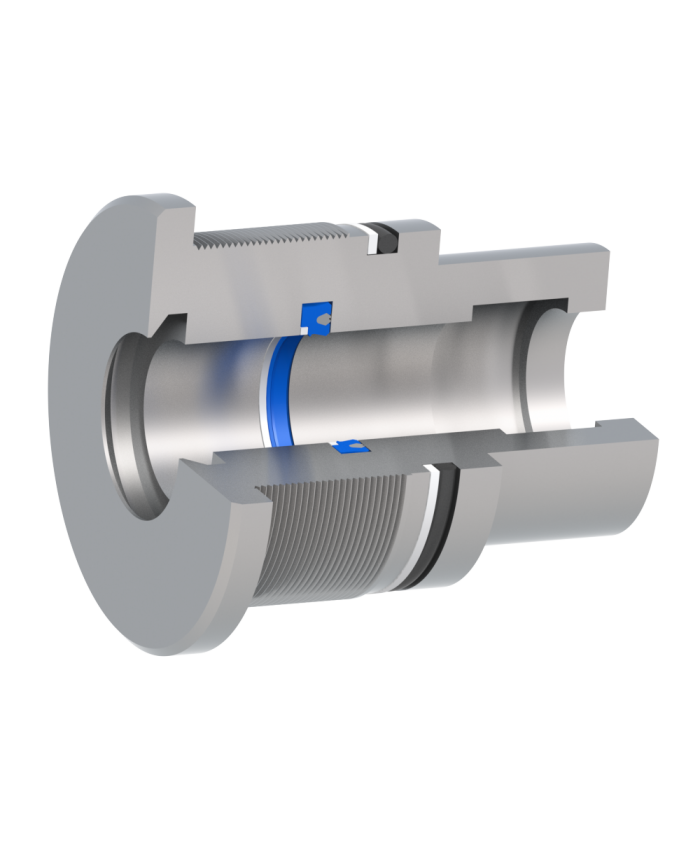

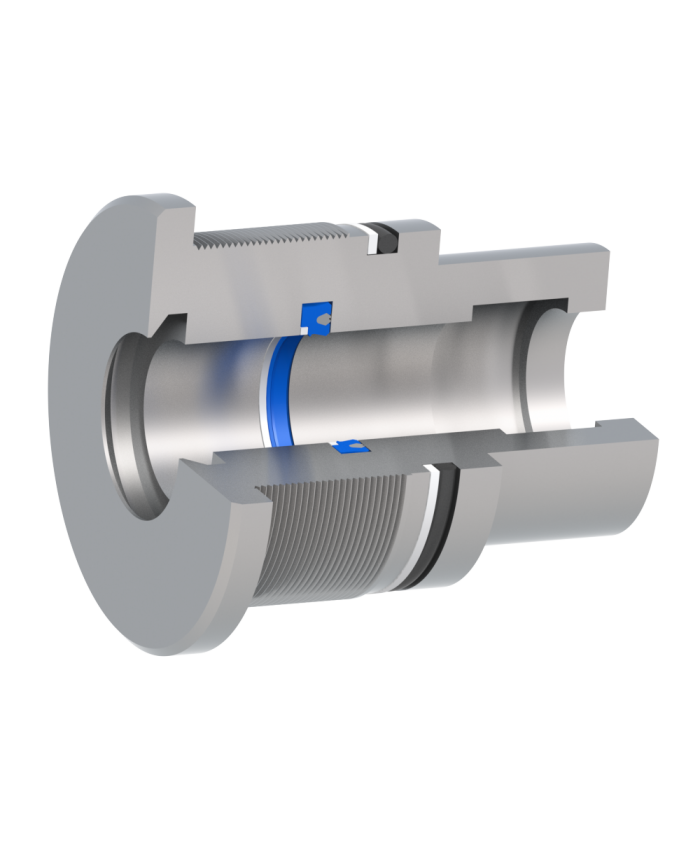

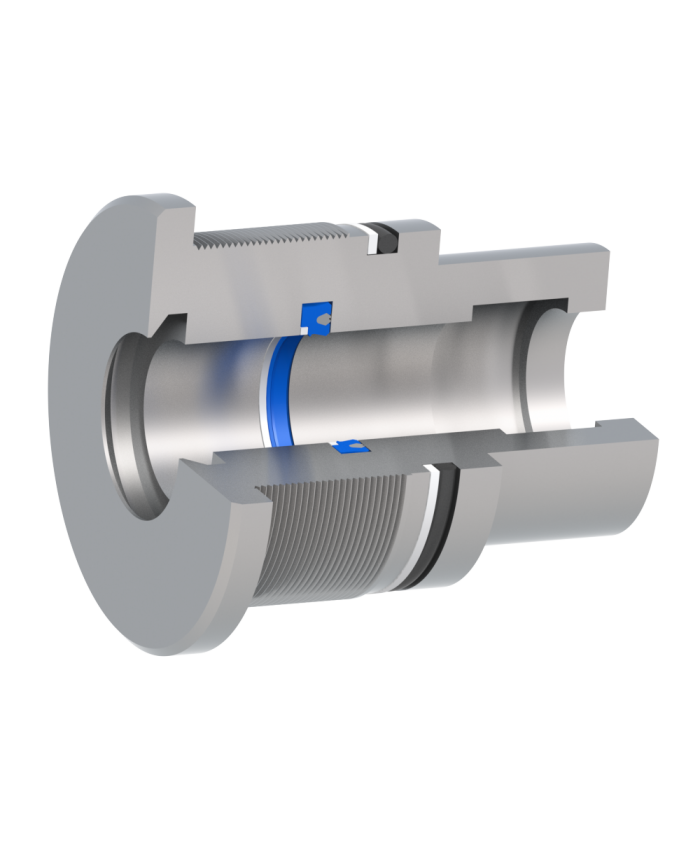

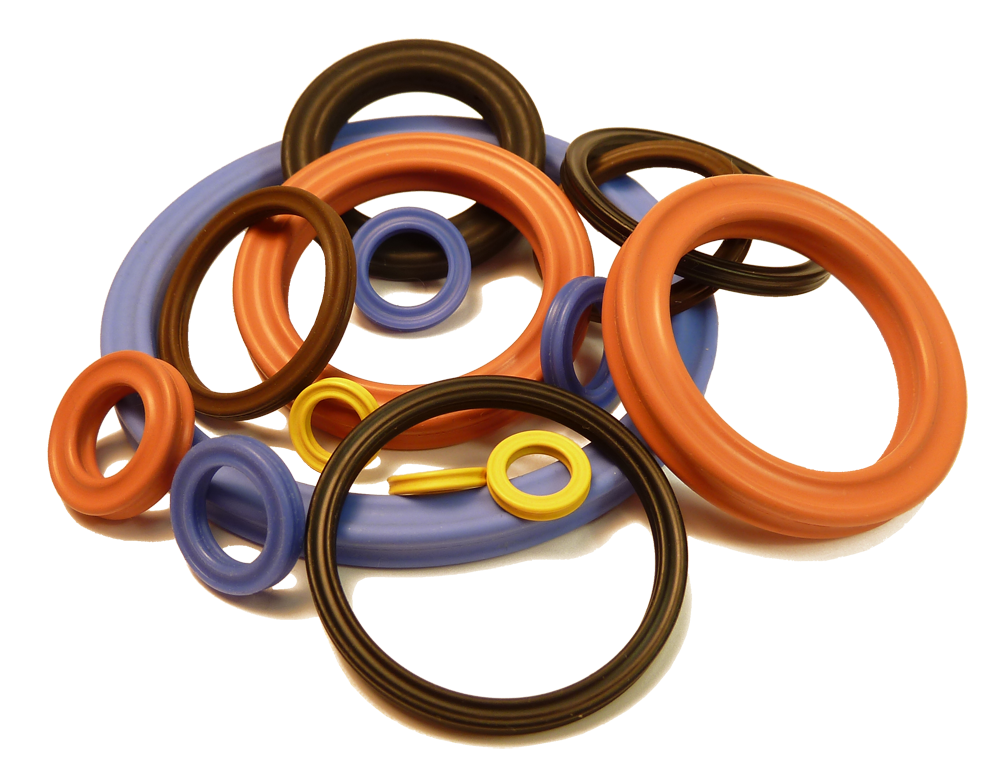

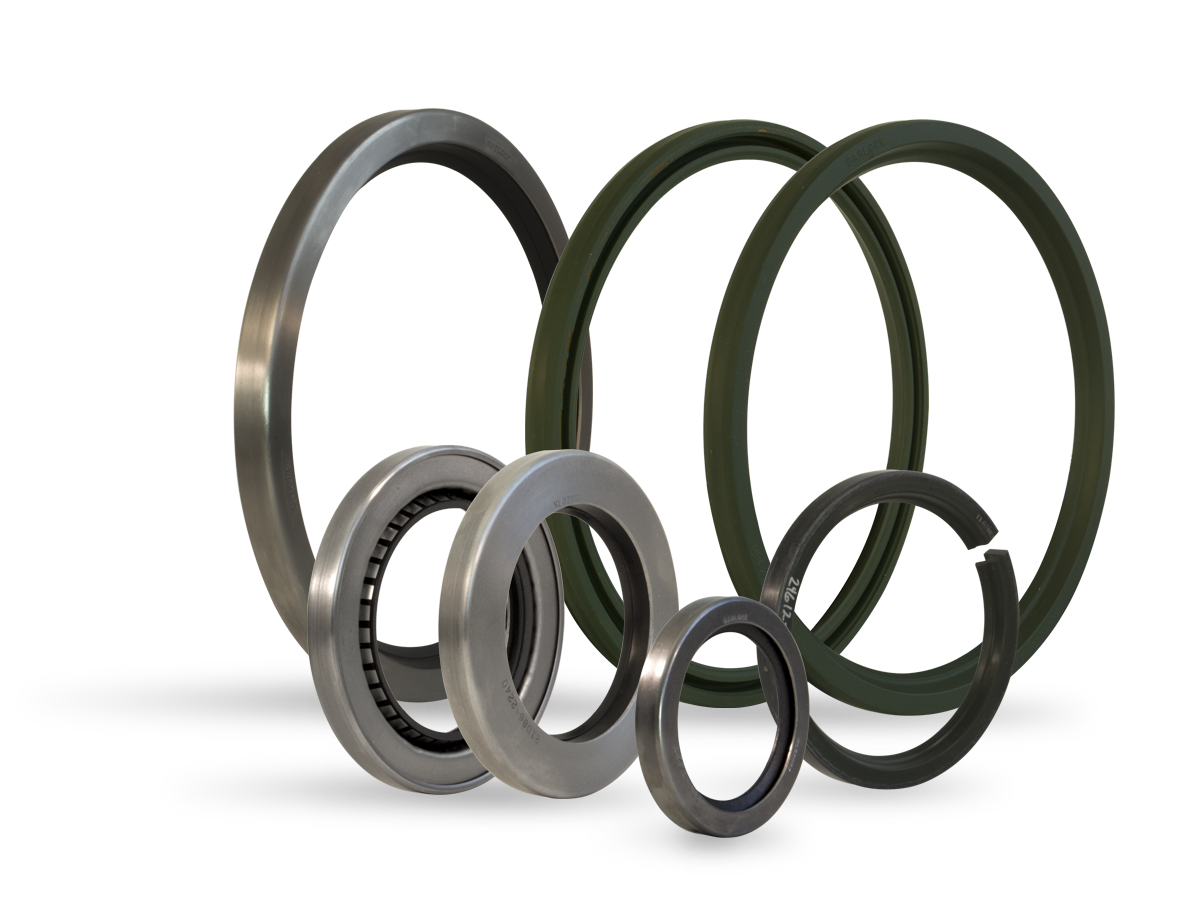

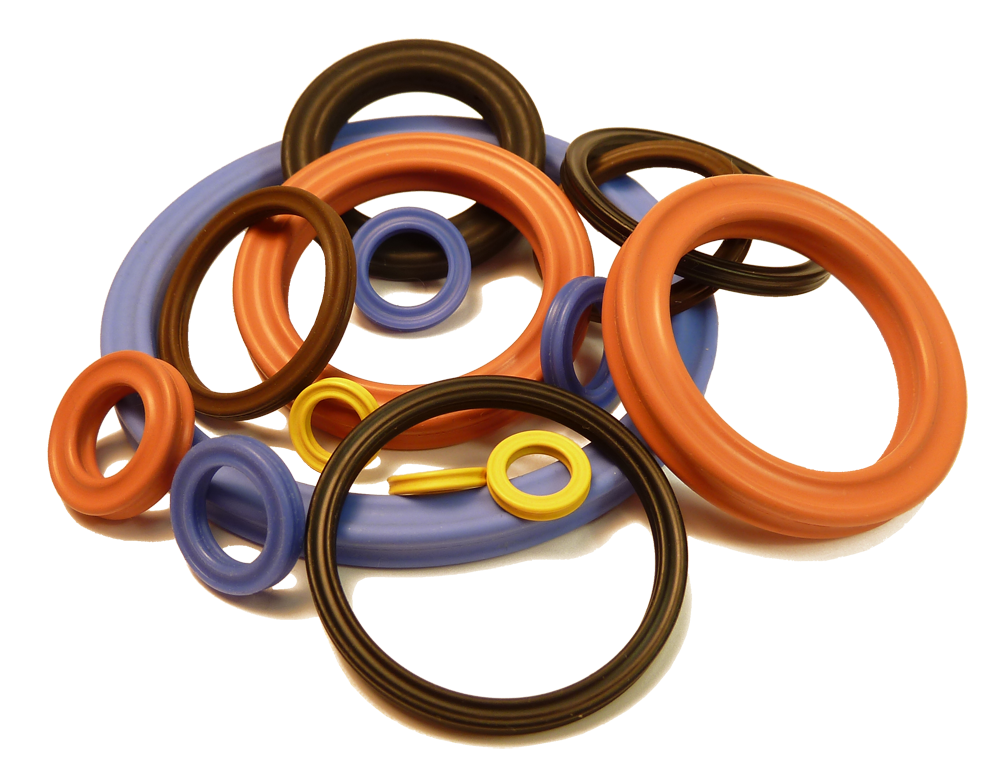

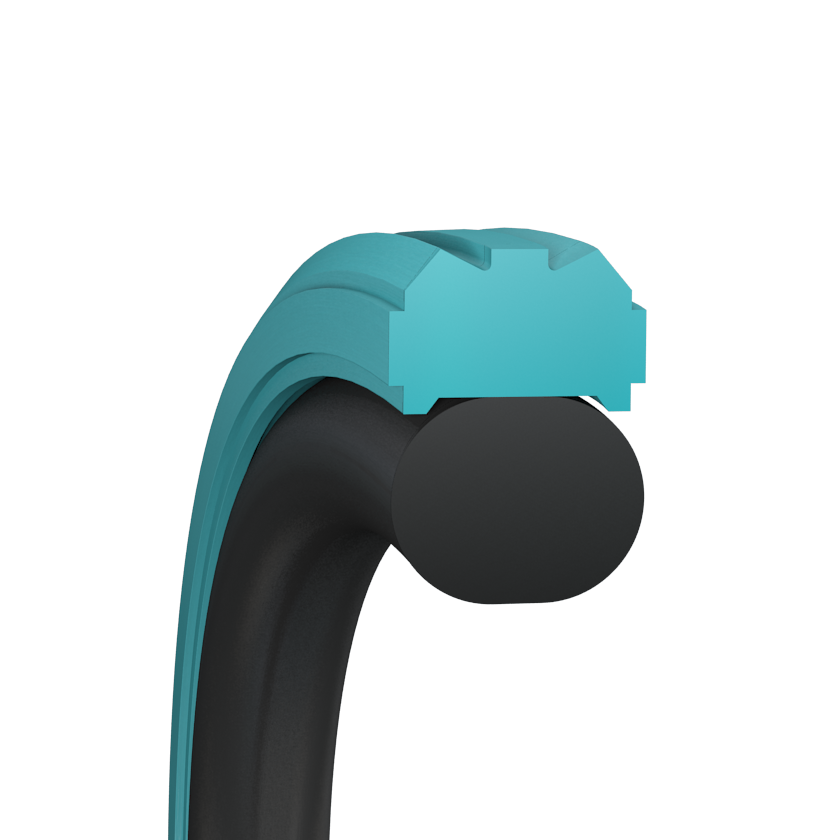

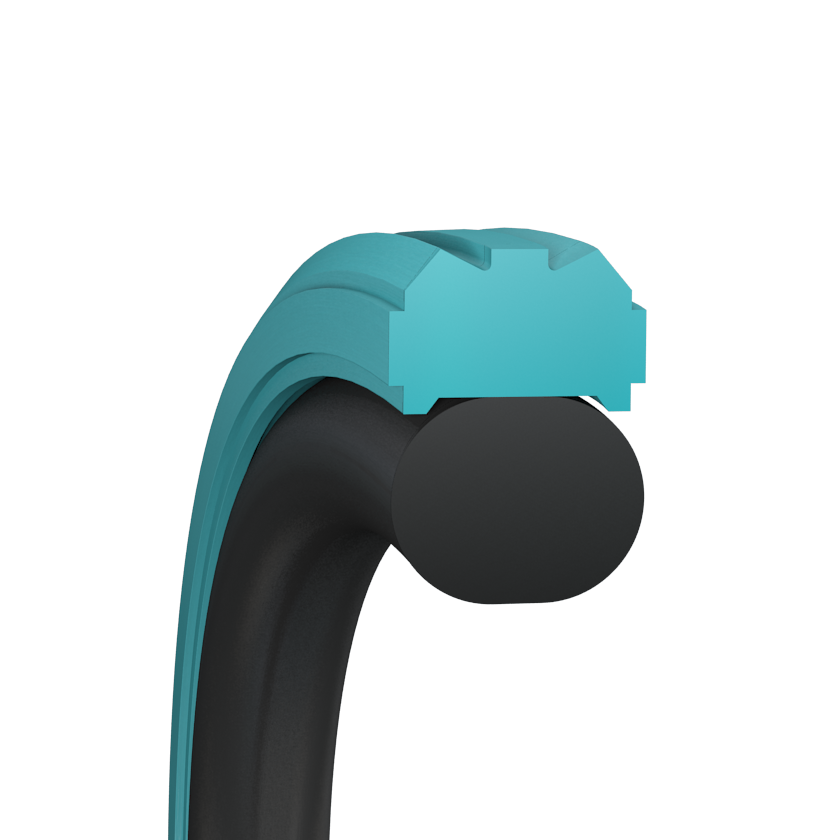

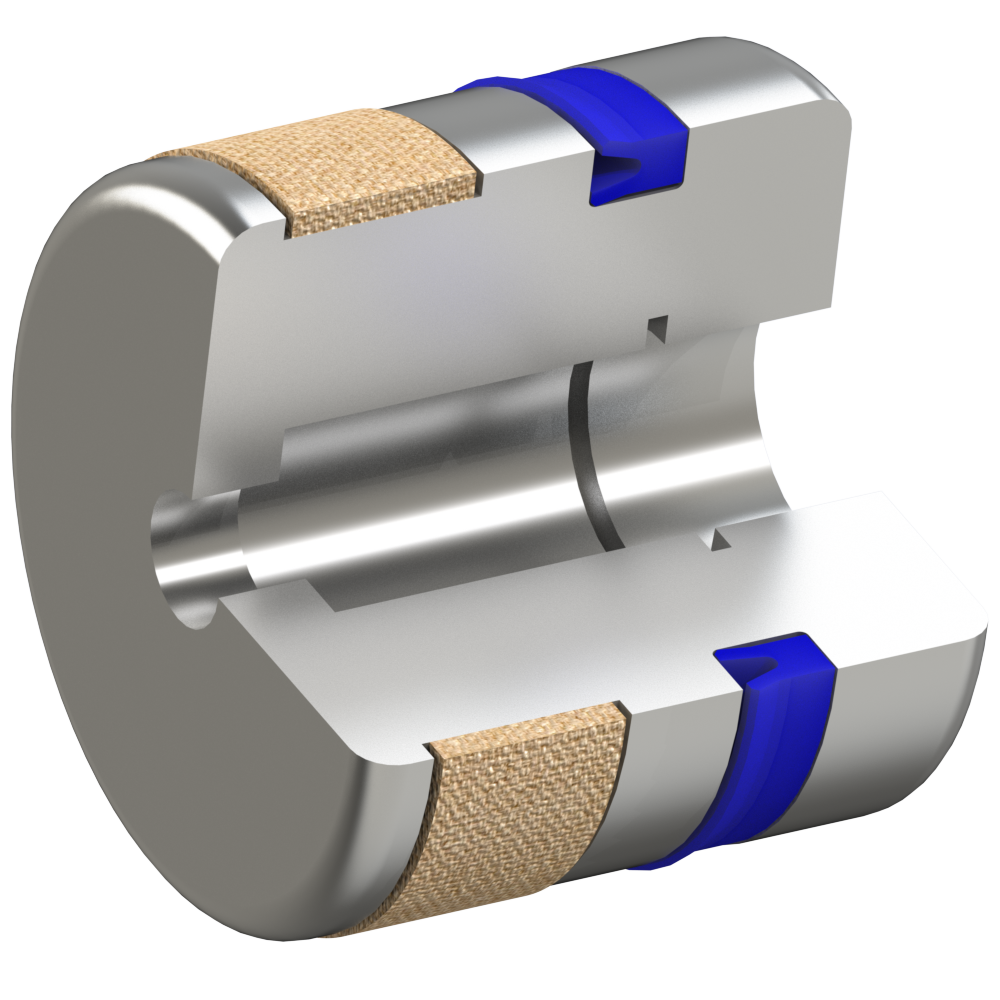

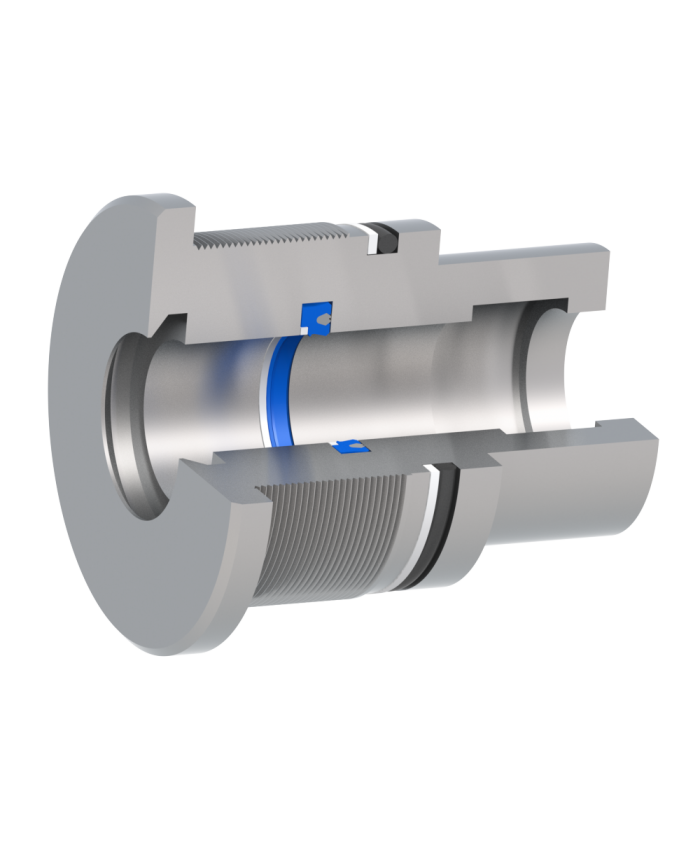

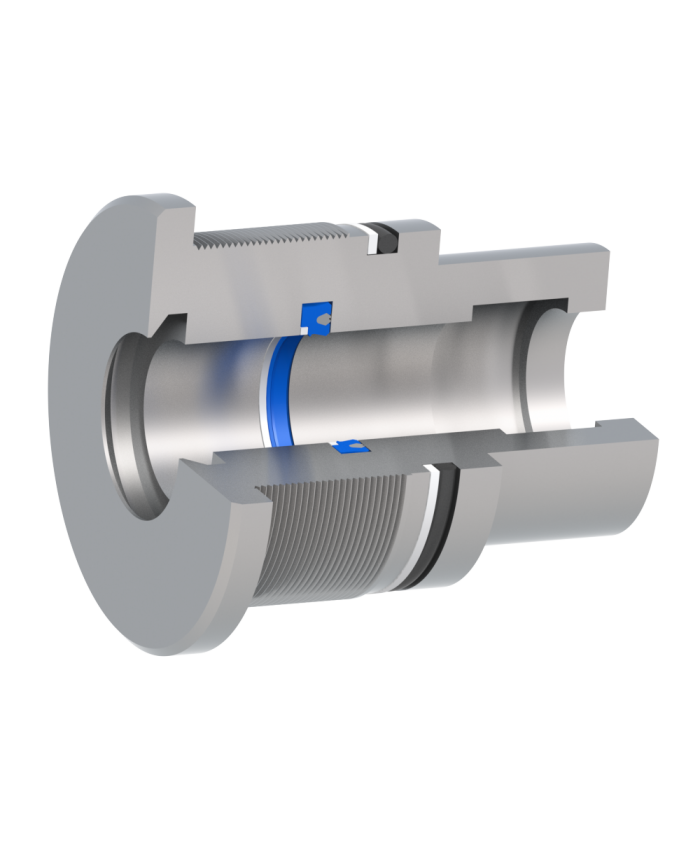

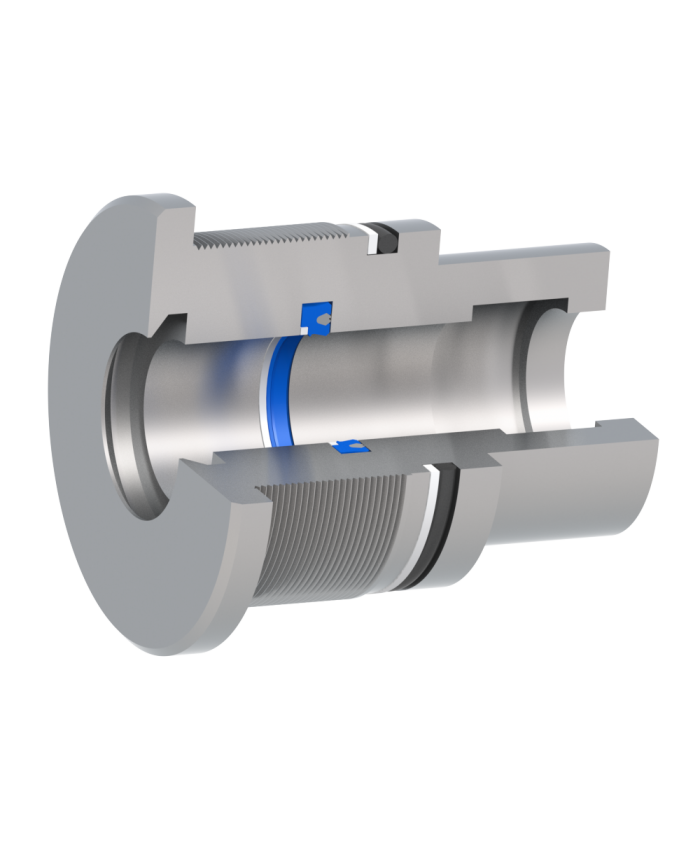

| Color Code:

Blue Nut, Grey Sub |

Compatible with other brands

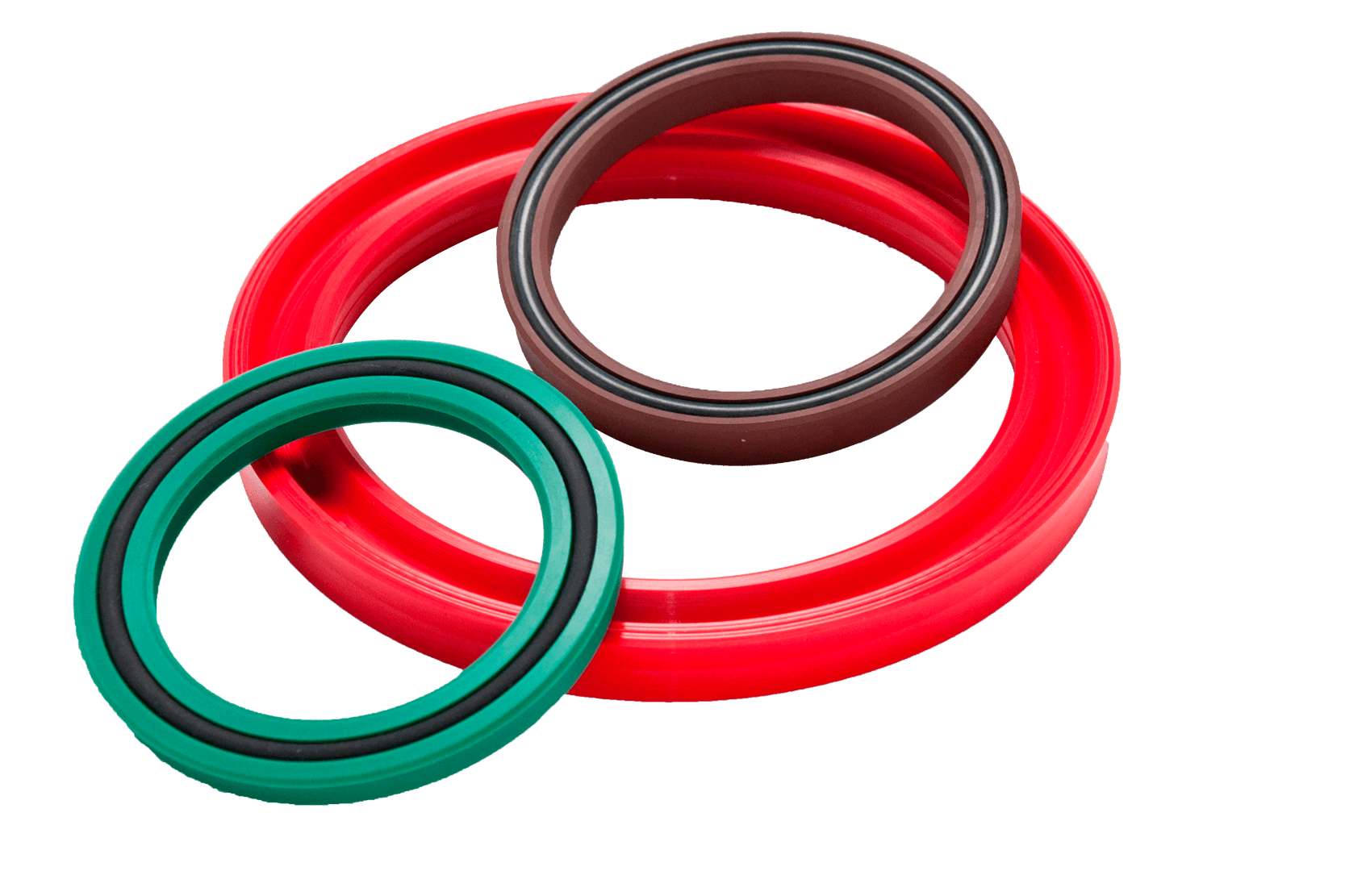

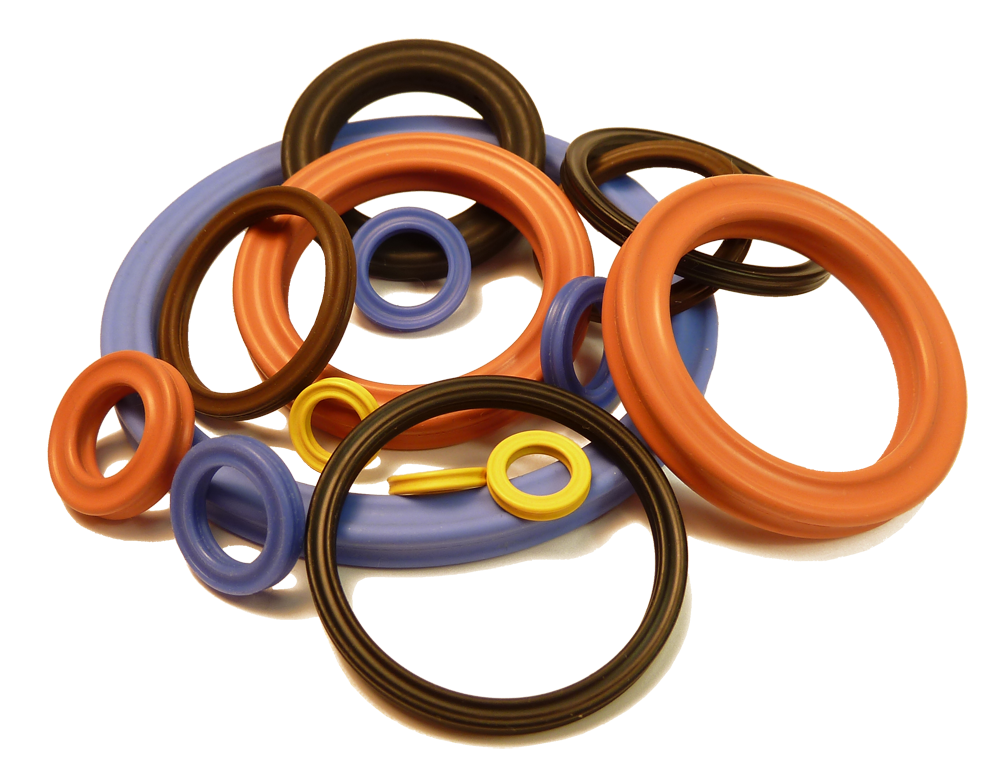

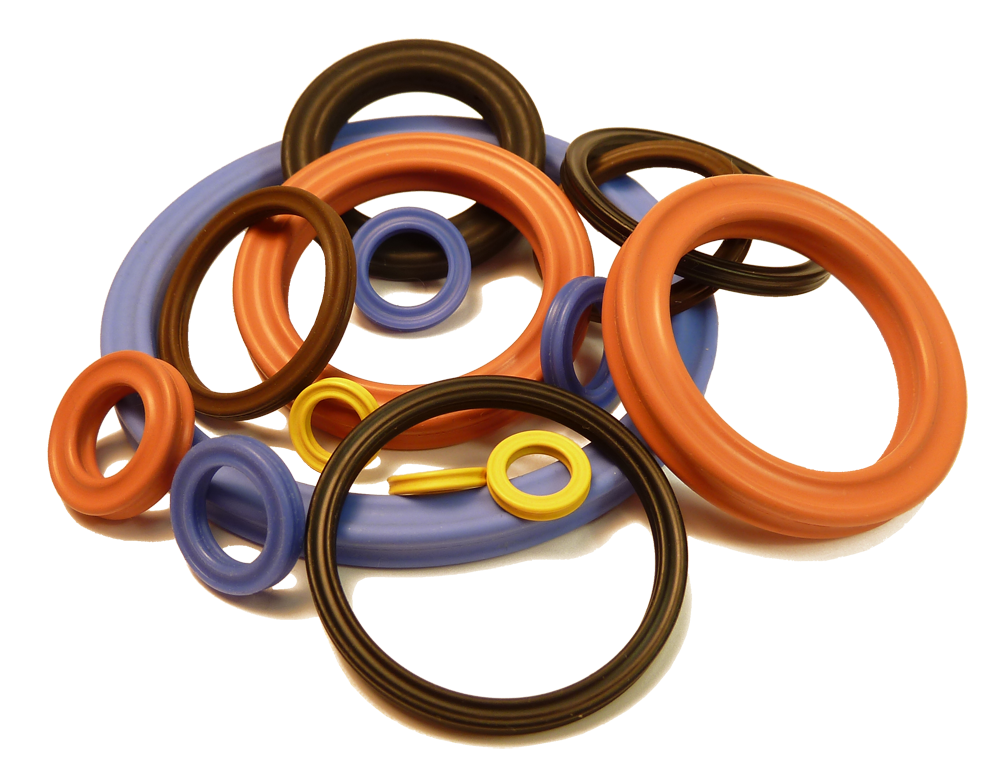

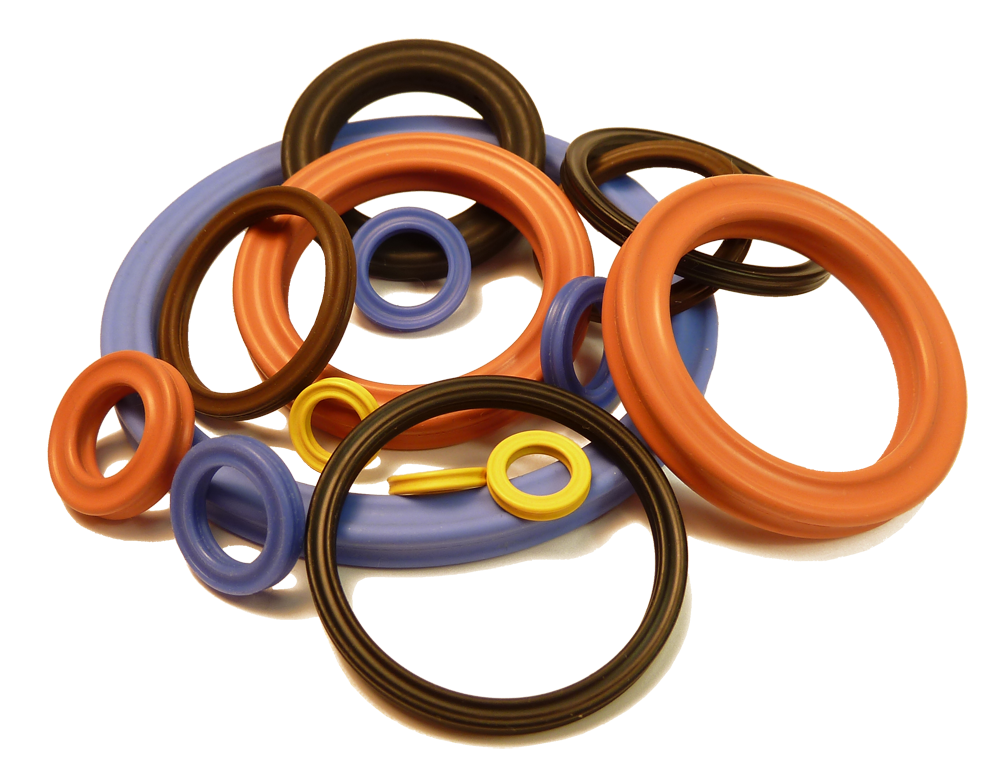

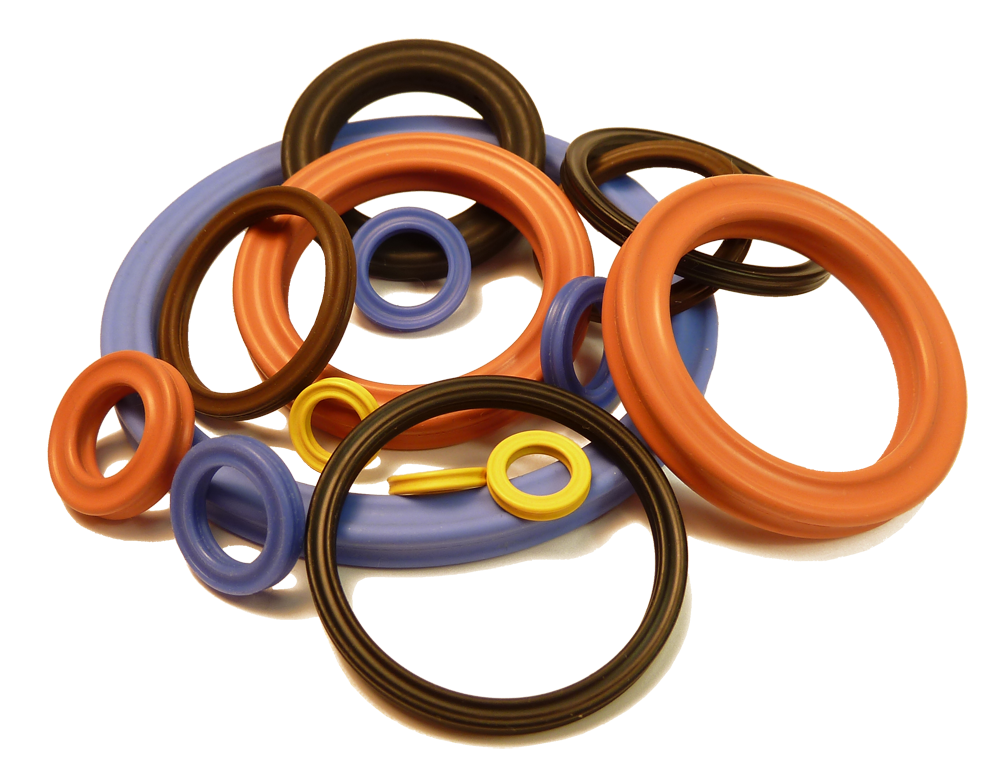

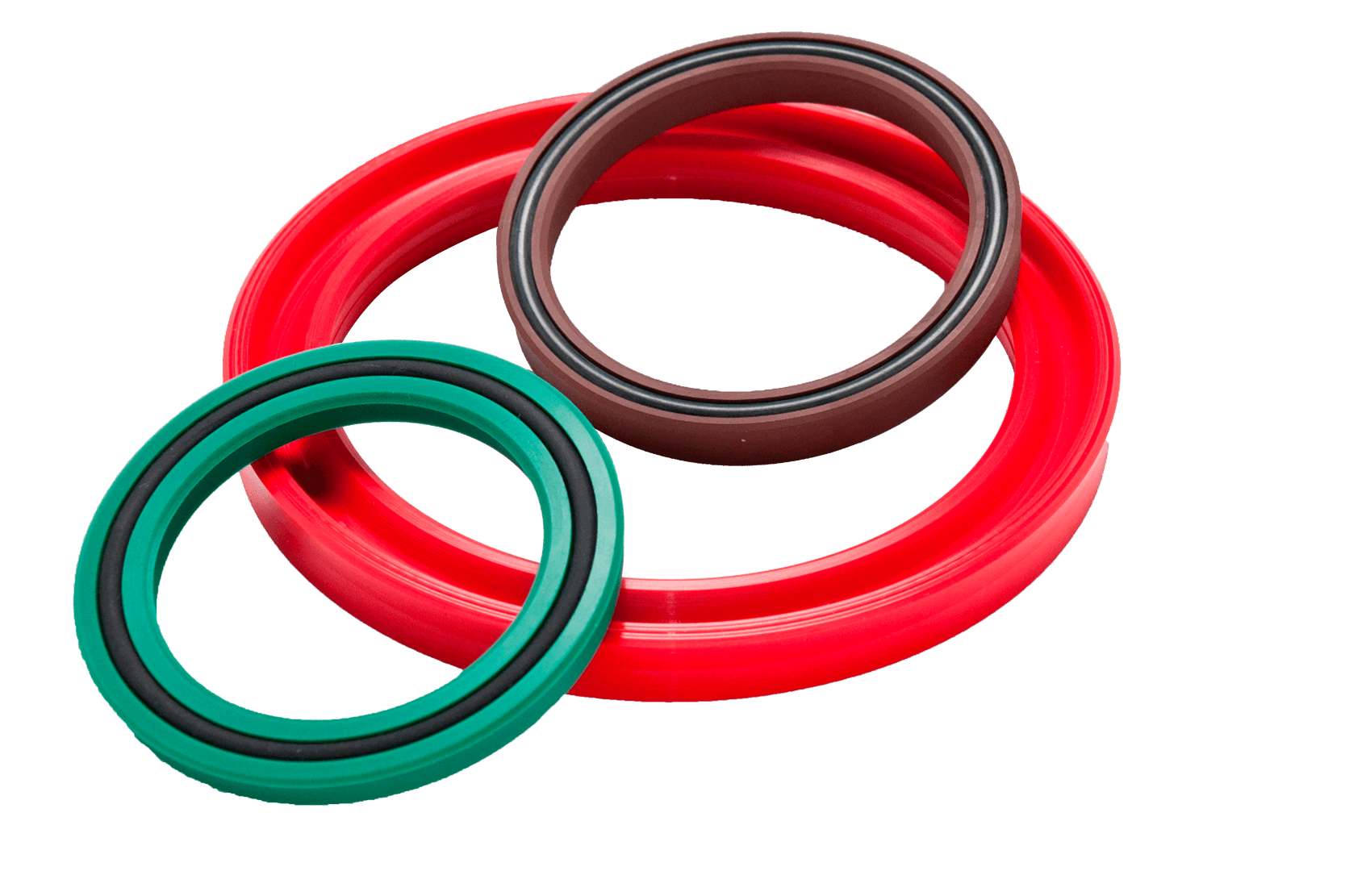

NBR/Nitrile (standard service), Viton® (sour gas service)

| Size | Nut Radius | Length Total | Pressure Rating (PSI) | Weight (LBS) | |||

| Inches | Inches | Inches |

Standard Service |

Sour Gas Service |

(Approx.) | ||

|

Cold Working |

Test |

Cold Working |

Test | ||||

| 1 | 1.96 | 2.65 | 2000 | 3000 | 2000 | 3000 | 1.75 |

| 1-1/4 | 2.17 | 2.78 | 2000 | 3000 | 2000 | 3000 | 2.37 |

| 1-1/2 | 2.41 | 2.98 | 2000 | 3000 | 2000 | 3000 | 3.29 |

| 2 | 2.90 | 3.17 | 2000 | 3000 | 2000 | 3000 | 5.47 |

| 2-1/2 | 3.63 | 4.13 | 2000 | 3000 | 2000 | 3000 | 10.00 |

| 3 | 4.26 | 4.58 | 2000 | 3000 | 2000 | 3000 | 15.03 |

| 4 | 5.00 | 4.94 | 2000 | 3000 | 2000 | 3000 | 20.95 |

| 5 | 5.50 | 6.55 | 2000 | 3000 | 2000 | 3000 | 33.26 |

| 6 | 6.43 | 6.66 | 2000 | 3000 | 2000 | 3000 | 42.50 |

| 8 | 7.43 | 7.19 | 2000 | 3000 | 2000 | 3000 | 64.00 |

| 10 | 9.00 | 9.13 | 2000 | 3000 | 2000 | 3000 |

91.00 |

Diyak Ltd

Diyak Ltd